Know-how / Fiberglass / Production / Accessories / Customization / Logistics / Products / Video

Fiberglass

and accessories for ETICS

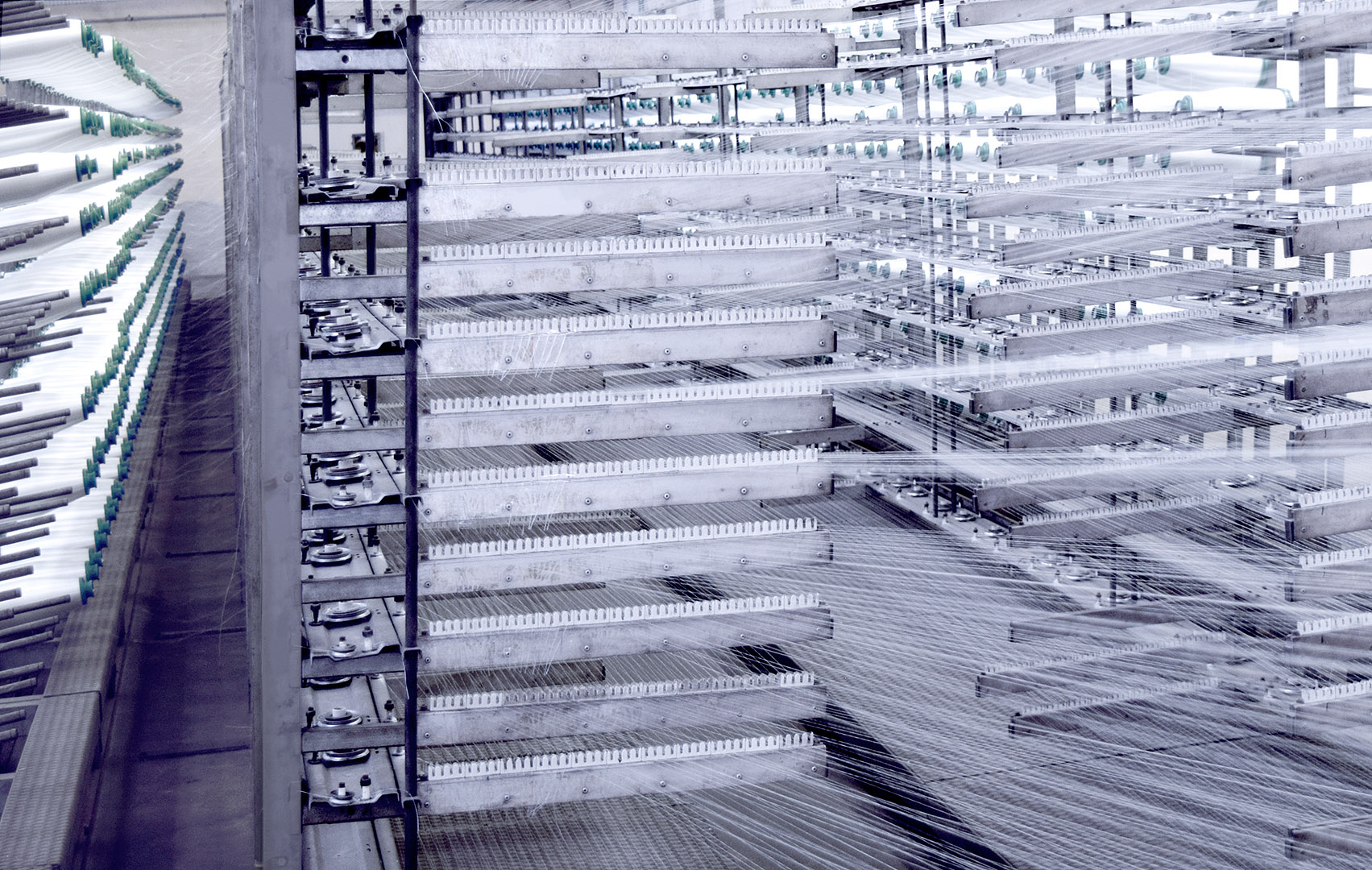

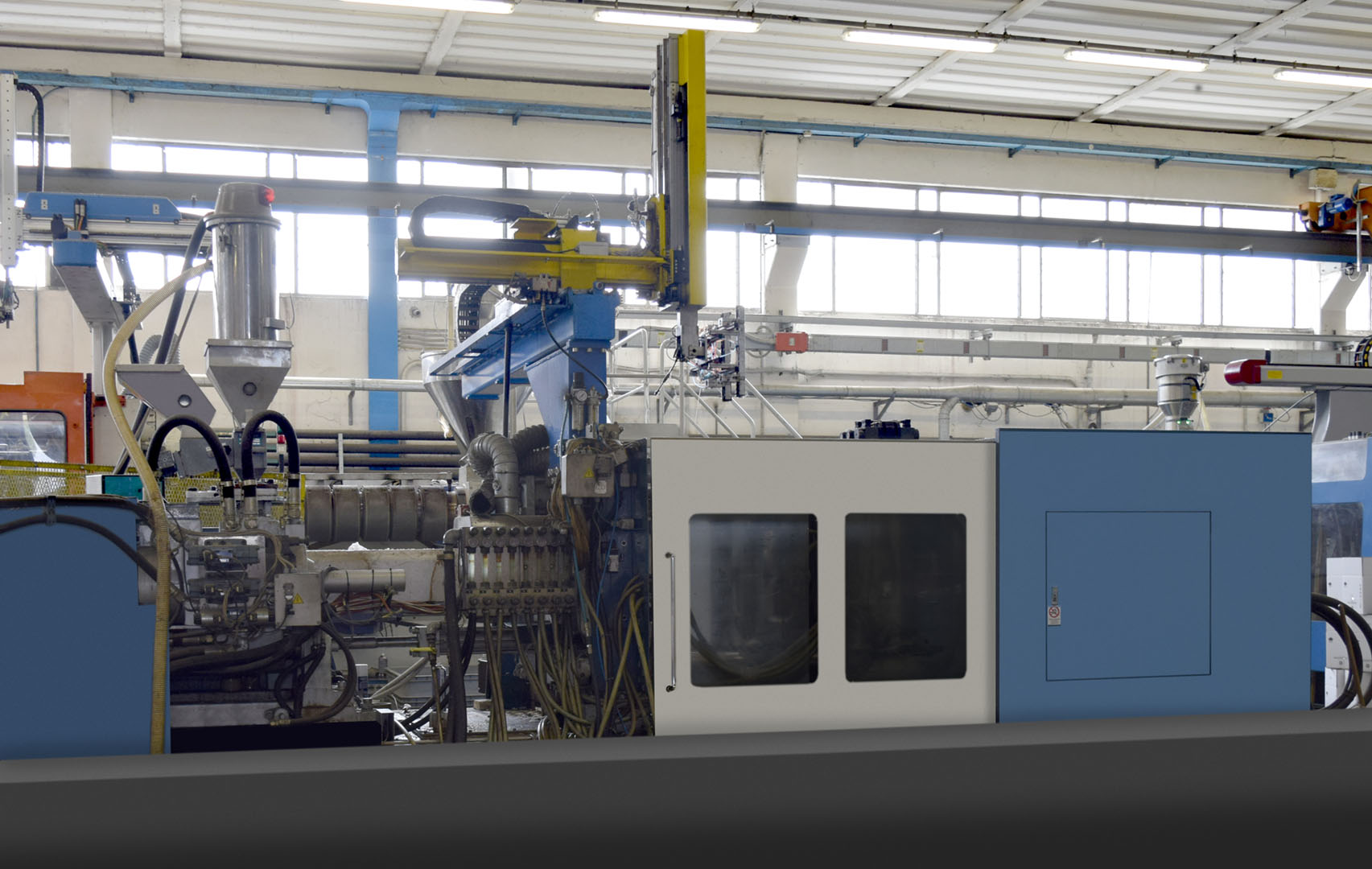

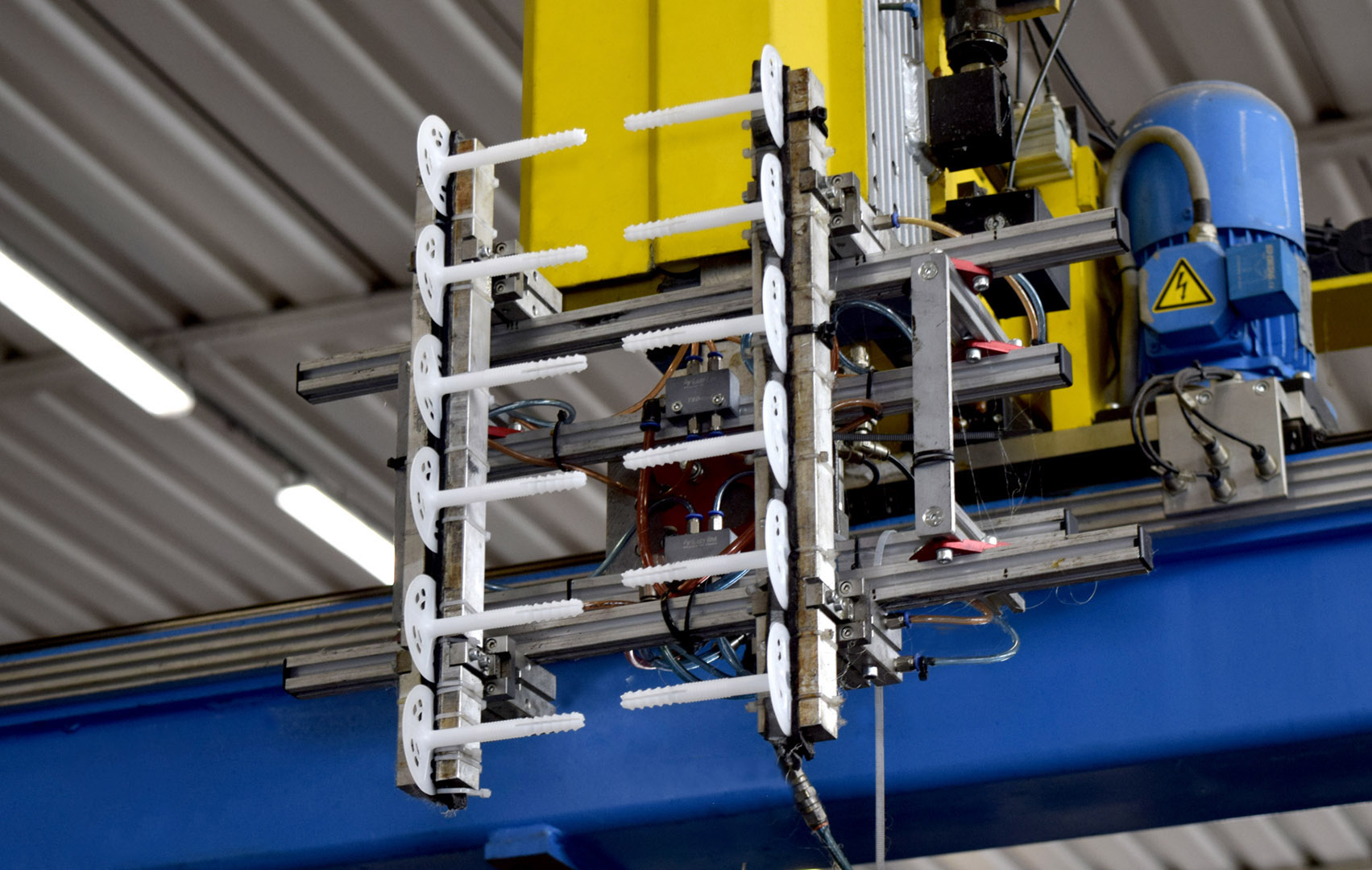

The know-how acquired in more than 25 years of experience allows us to have a consolidated production capacity and an international reference market. We produce our products in the facilities located in Bergamo, Treviso and Lecce, in more than 20,000 total square meters and with the aid of technologically advanced installations. This allows us to have an independent and continuous cycle production, to be detached from problems related to external factors and to control directly the quality in all phases of production of our products.

The use of high-quality materials, our constantly updated technicians and the constant verification of processes, allow us to offer our customers a production strictly “Made in Italy”.

square meters of plants

Know-how / Fiberglass / Production / Accessories / Customization / Logistics / Products / Video

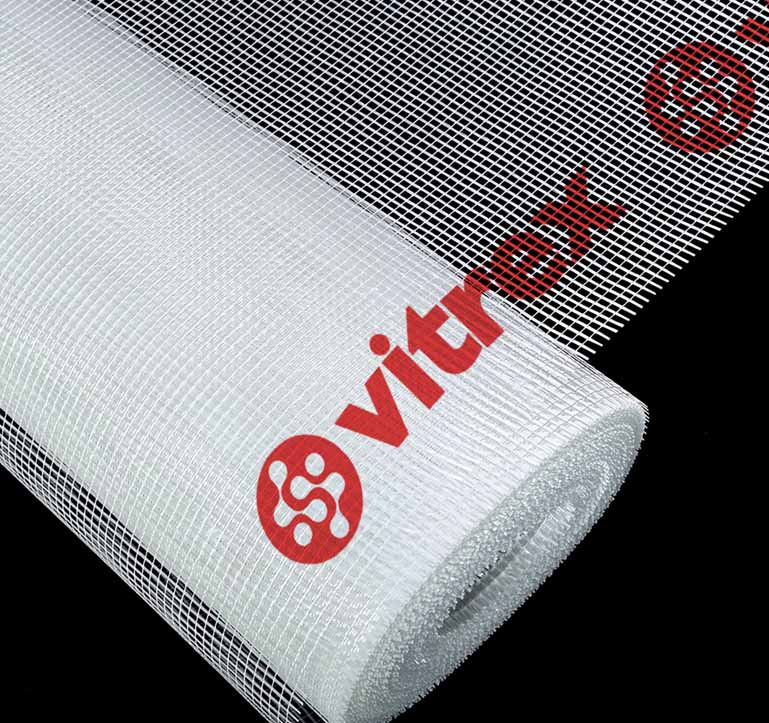

Fiberglass mesh

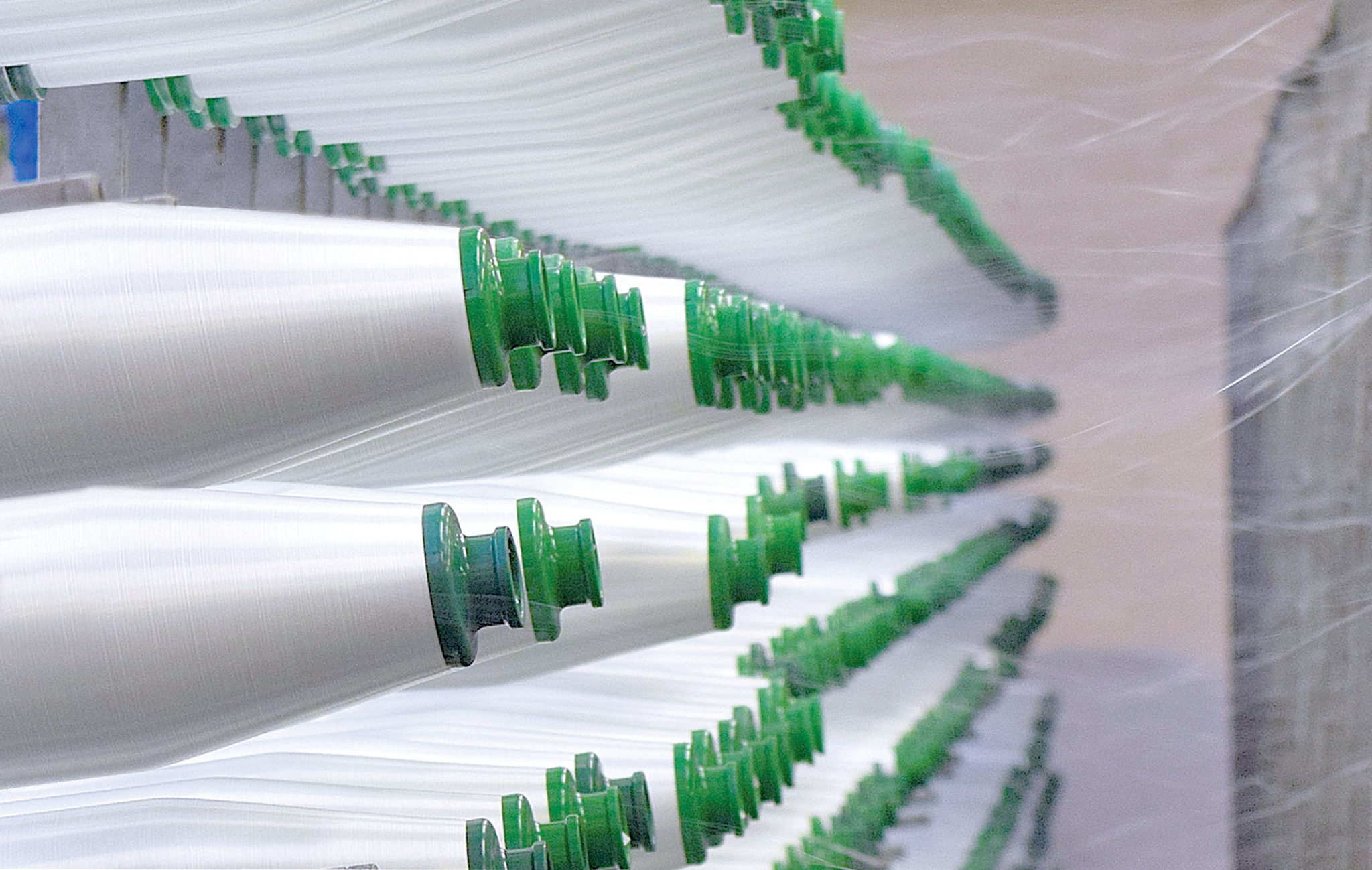

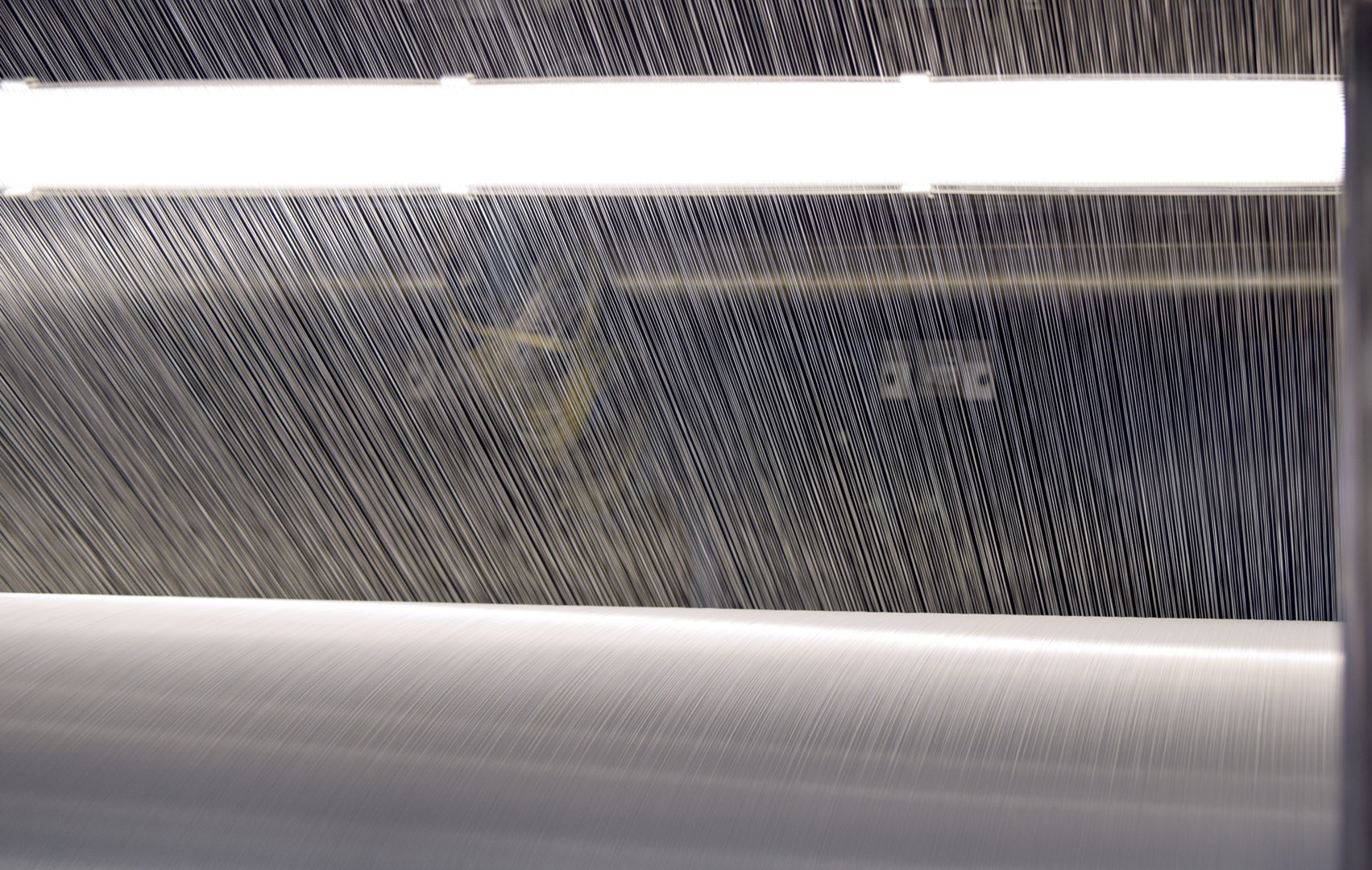

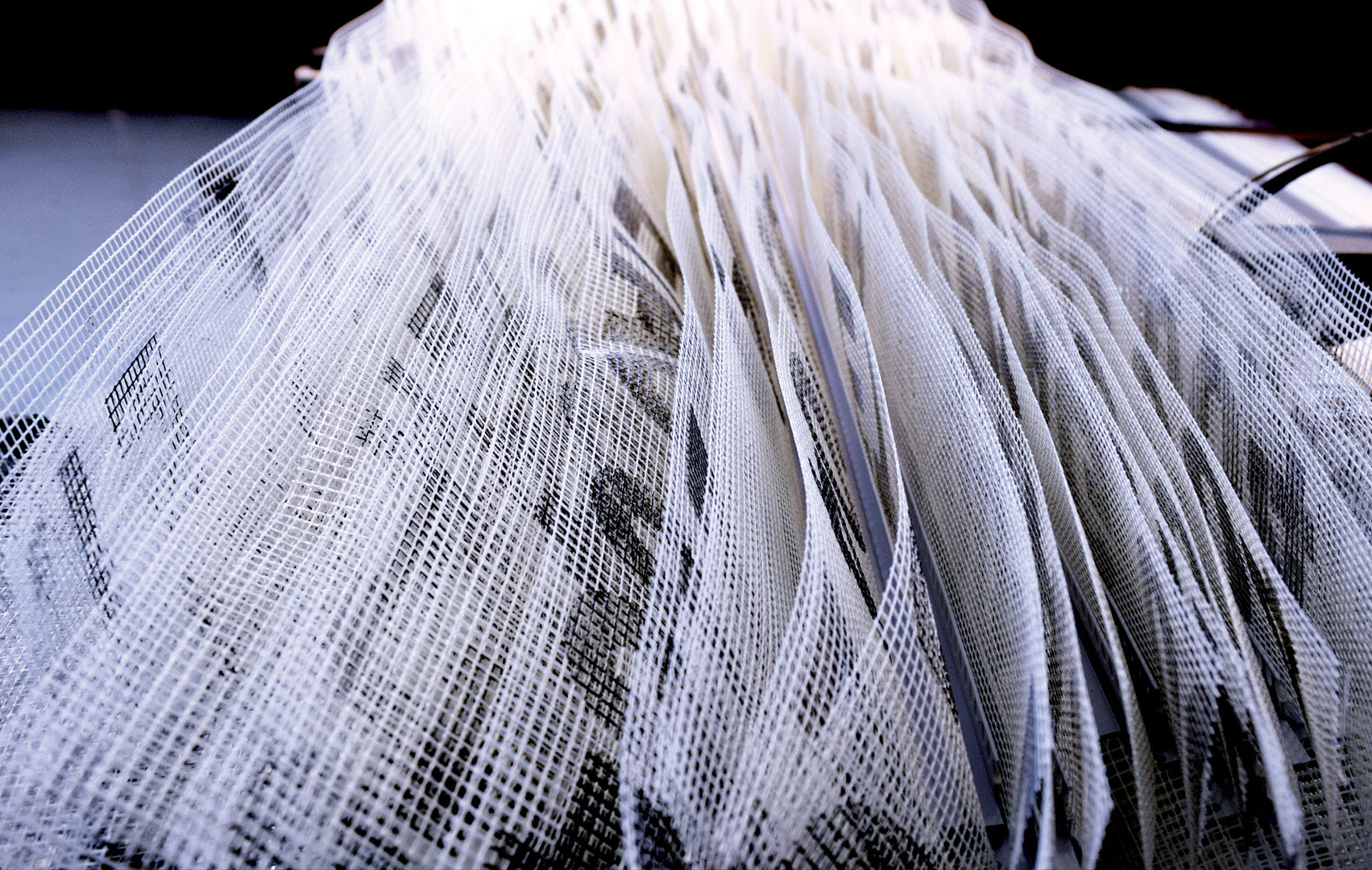

The use of high-quality raw materials is essential to obtain a finished product capable of guaranteeing high performance.

We use E-glass for its qualities of electrical insulation, high tensile strength and alkali resistance.

Both the glass fiber and the resins used are absolutely formaldehyde-free.

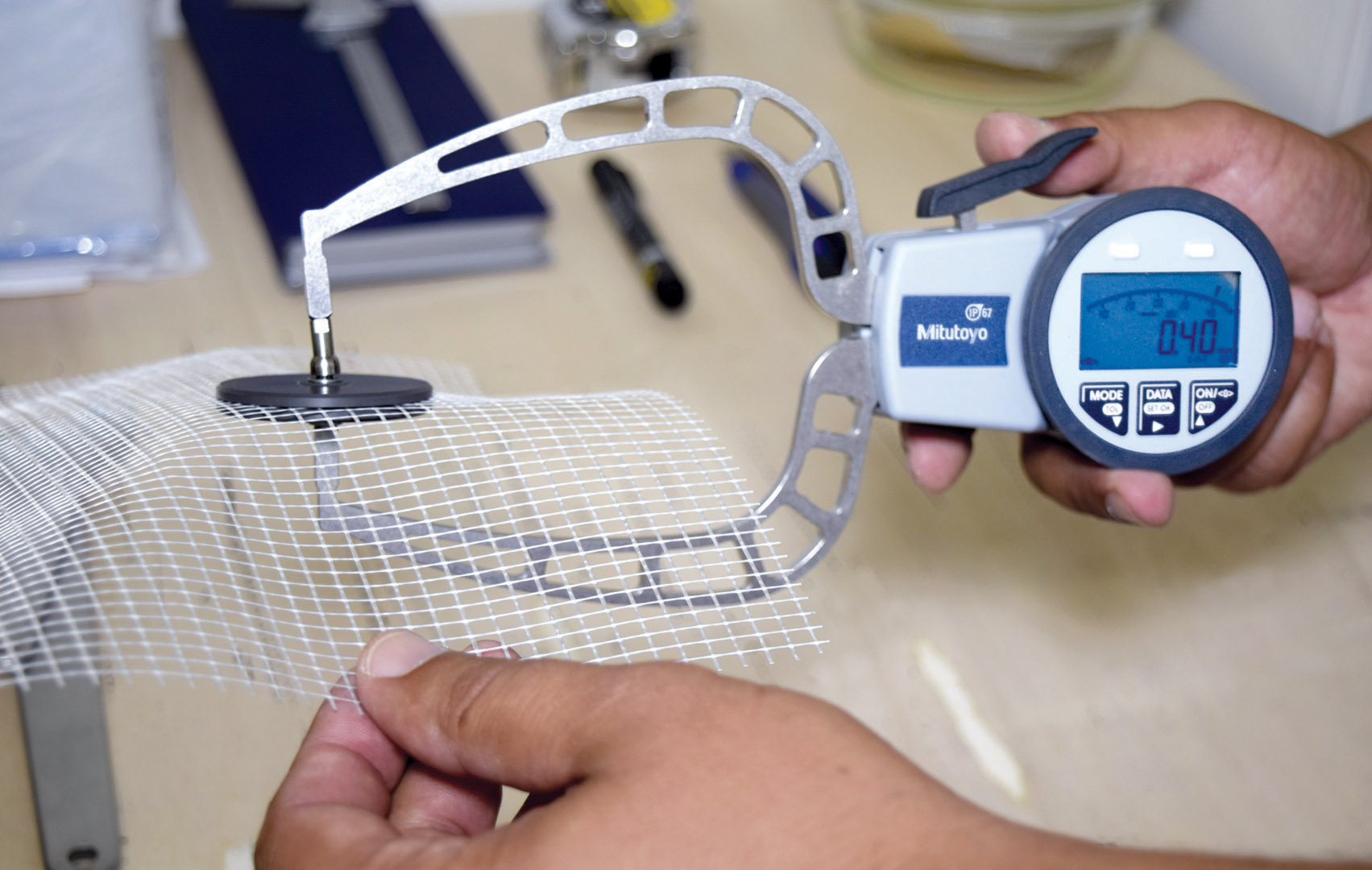

We carry out the first test of our products at the ITC-CNR institute to verify the quality performance we have set ourselves, then we maintain this quality standard through constant verification tests in our internal laboratories.

million square meters of fiberglass mesh produced every year

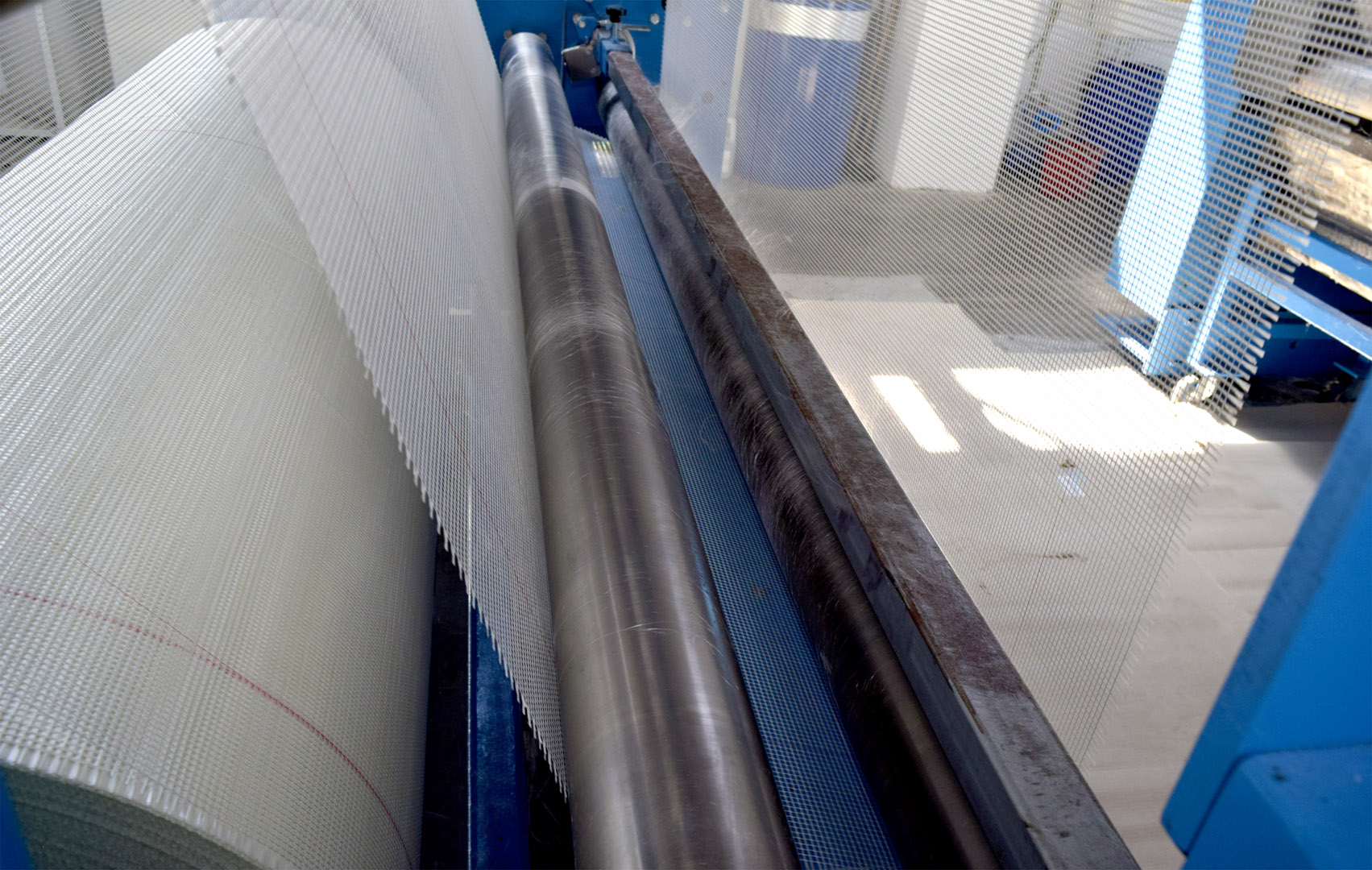

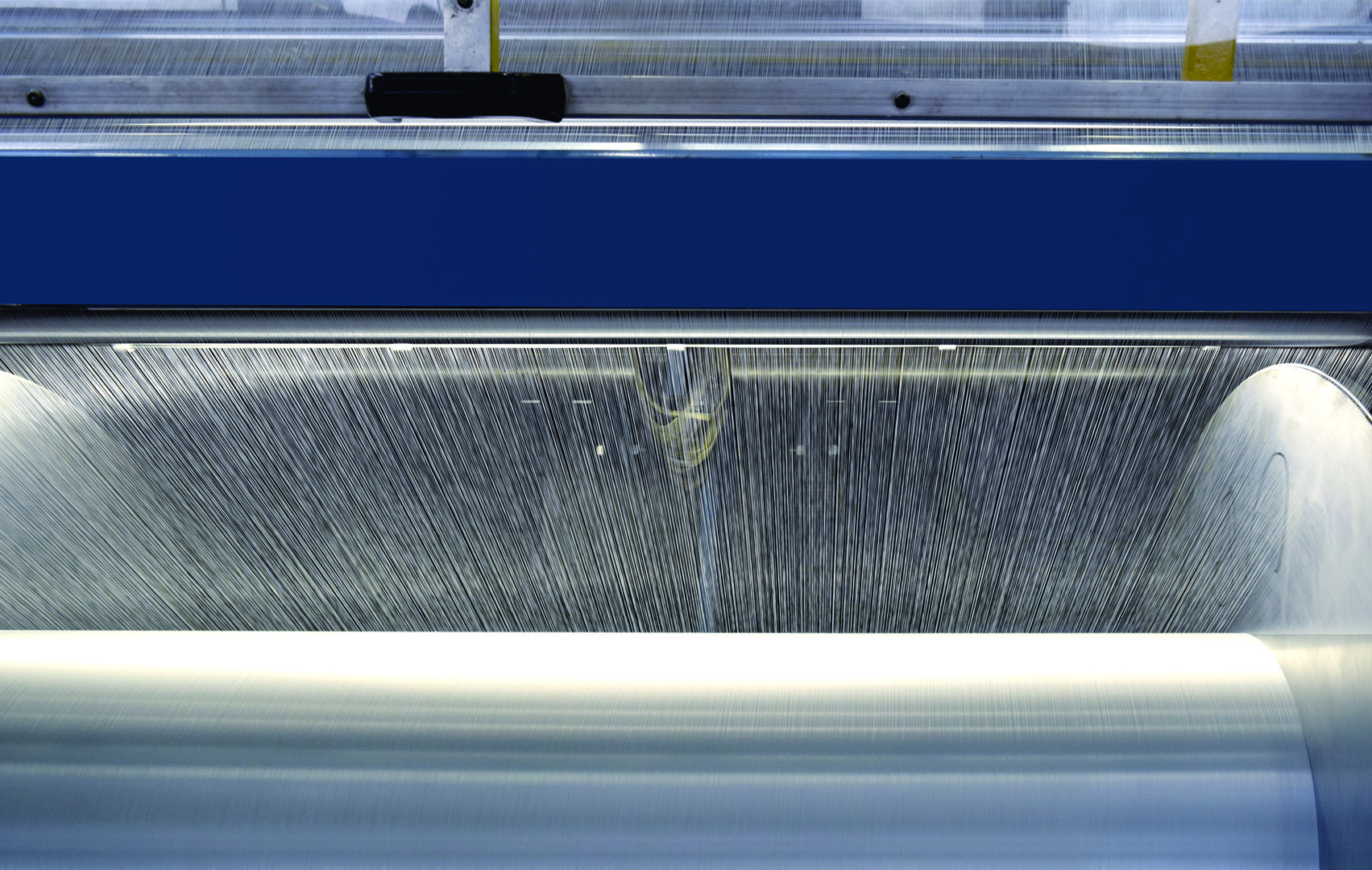

Coating process

Coating process

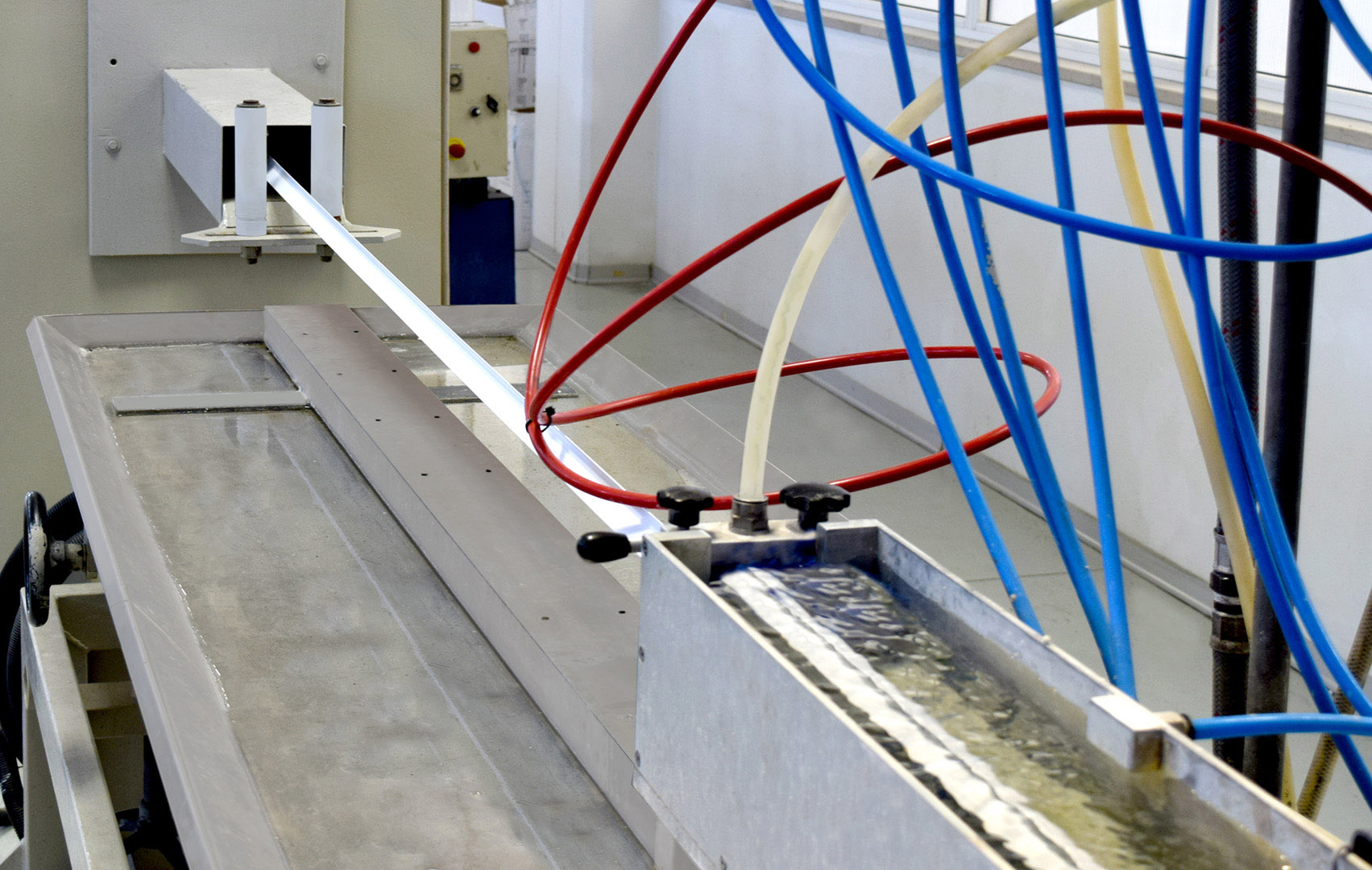

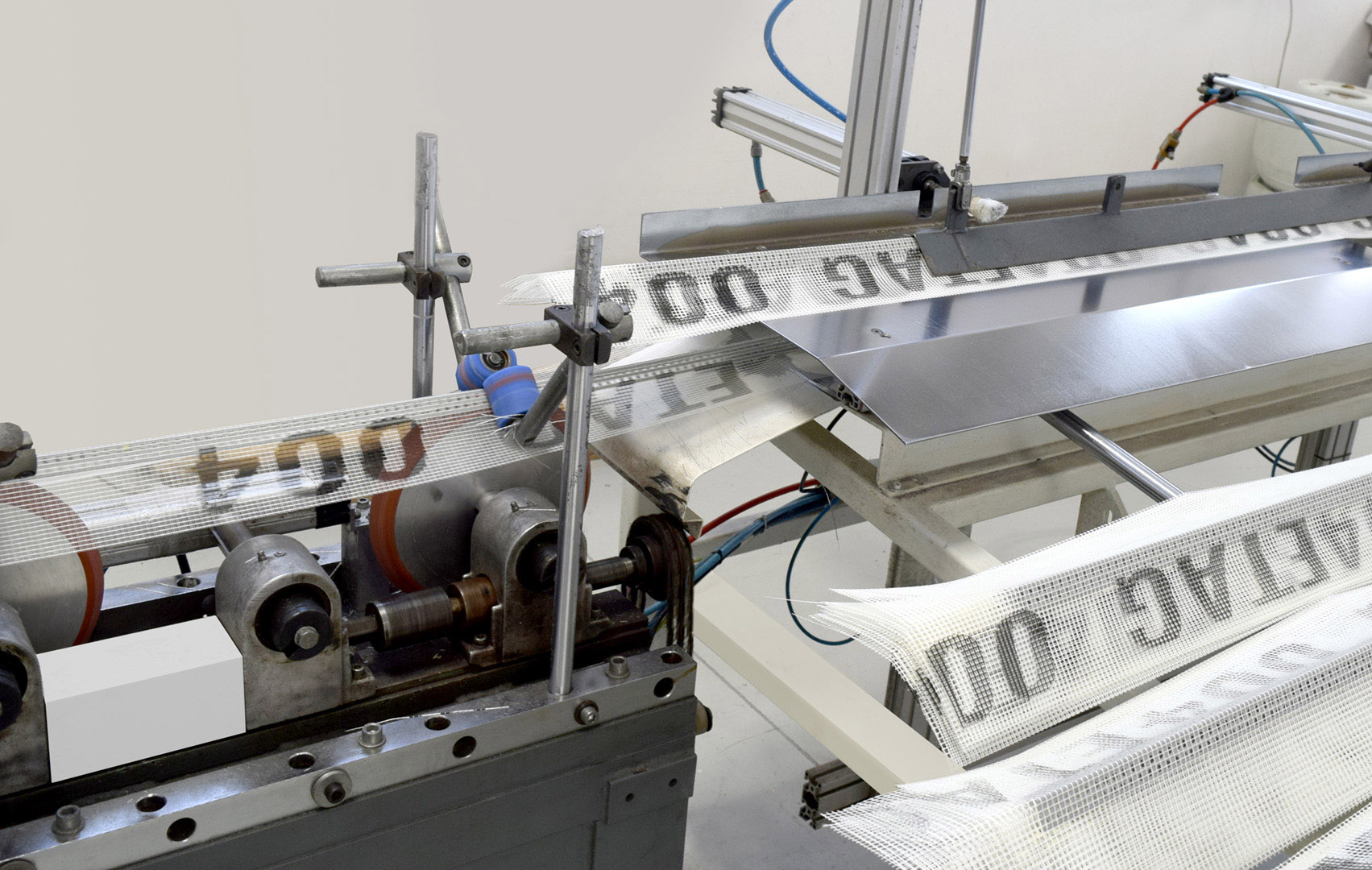

The coating process is not less important than the weaving and is fundamental to guarantee a high resistance, the cohesion of the yarns and a high quality to the finished product.

For this reason we use SBR water-based resins and free of solvents harmful to the environment, non-toxic and anticarcinogenic, which are diluted according to strict procedures with the aim of maximizing alkali resistance. This unlike the oriental producers, not bound by the strict European regulations, all this with obvious repercussions both on the final quality of the product and on the guarantees offered by the item it in terms of environmental protection and respect for health.

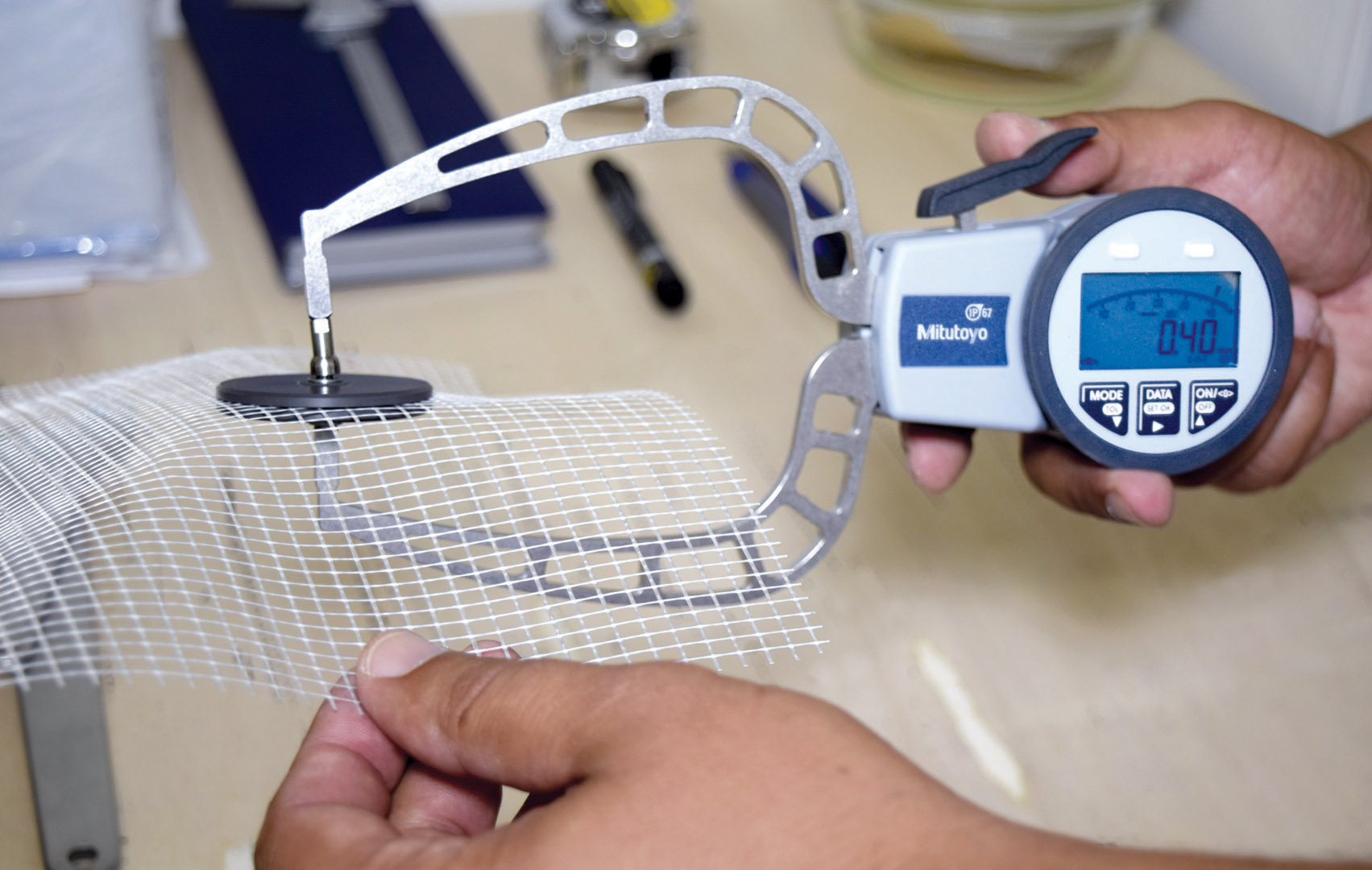

ETAG 004 - Test

Tests carried out in our laboratories for the quality control and maintenance of our products.

- Mesh size;

- Roll width;

- Weaving accuracy;

- Organic content;

- Mass per unit area;

- Thickness;

- Tensile strength and elongation;

- Tensile strength and elongation after ageing

- Heat combustion

Know-how / Fiberglass / Production / Accessories / Customization / Logistics / Products / Video

Fiber glass

Main production steps

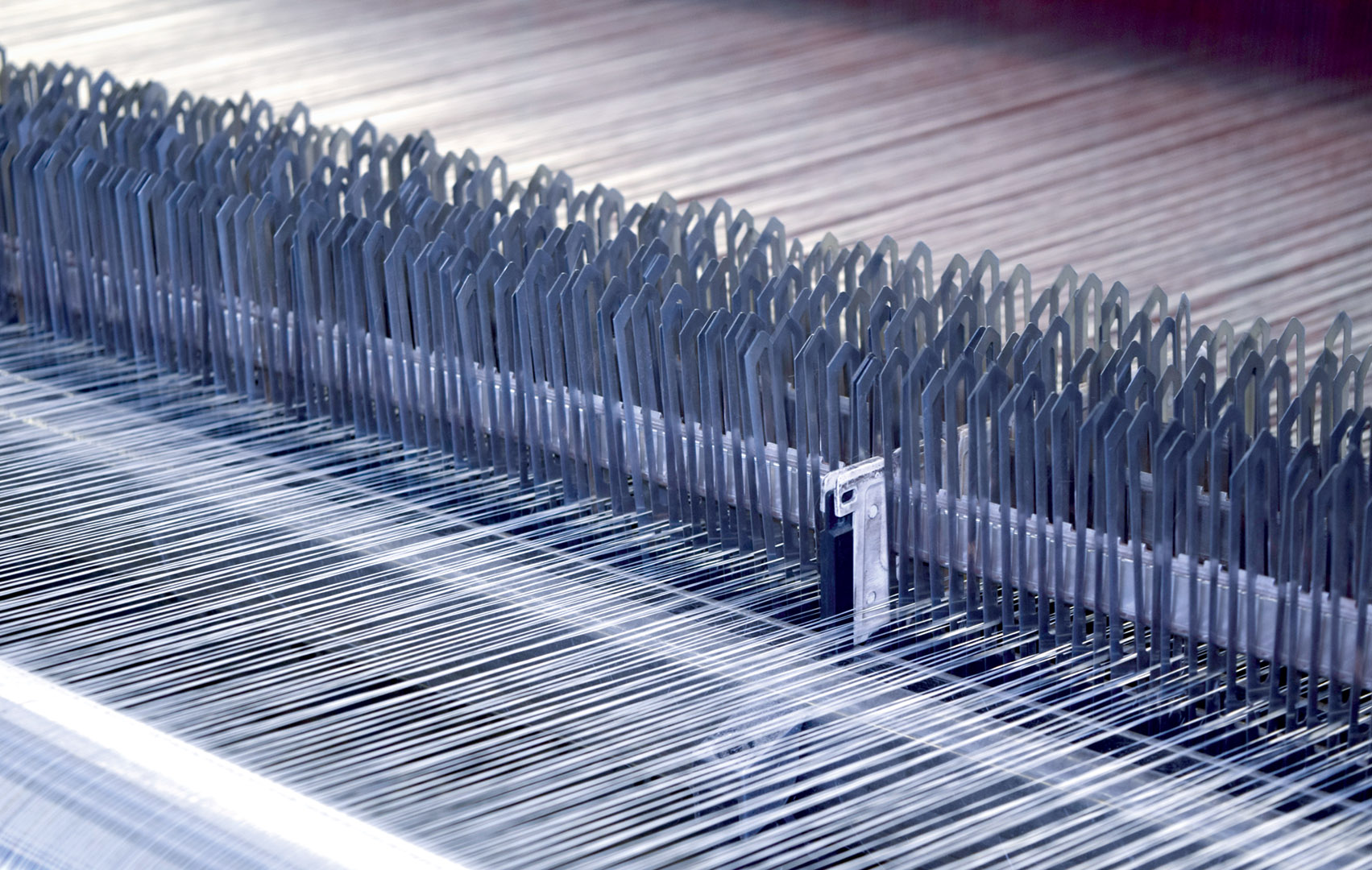

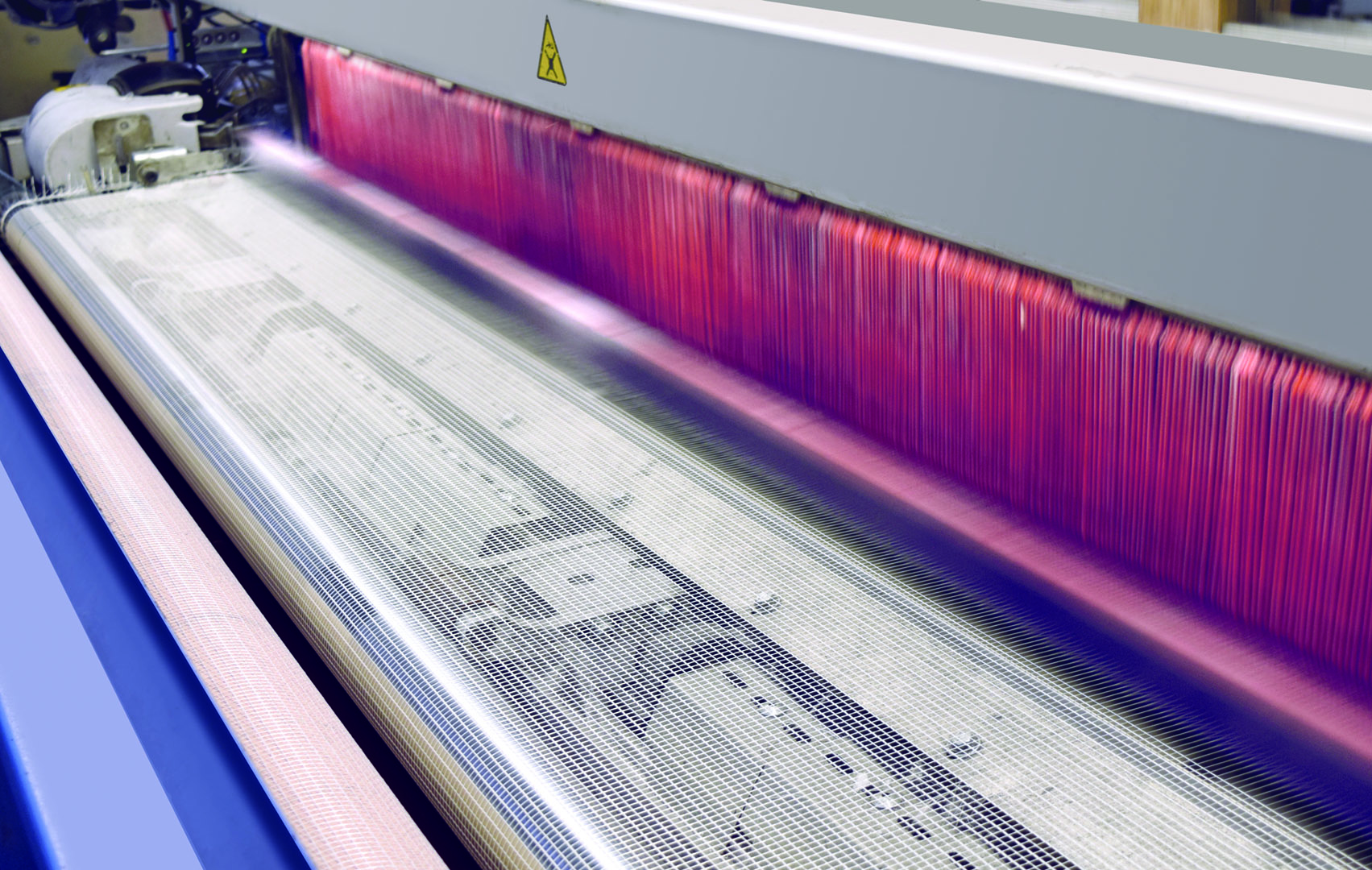

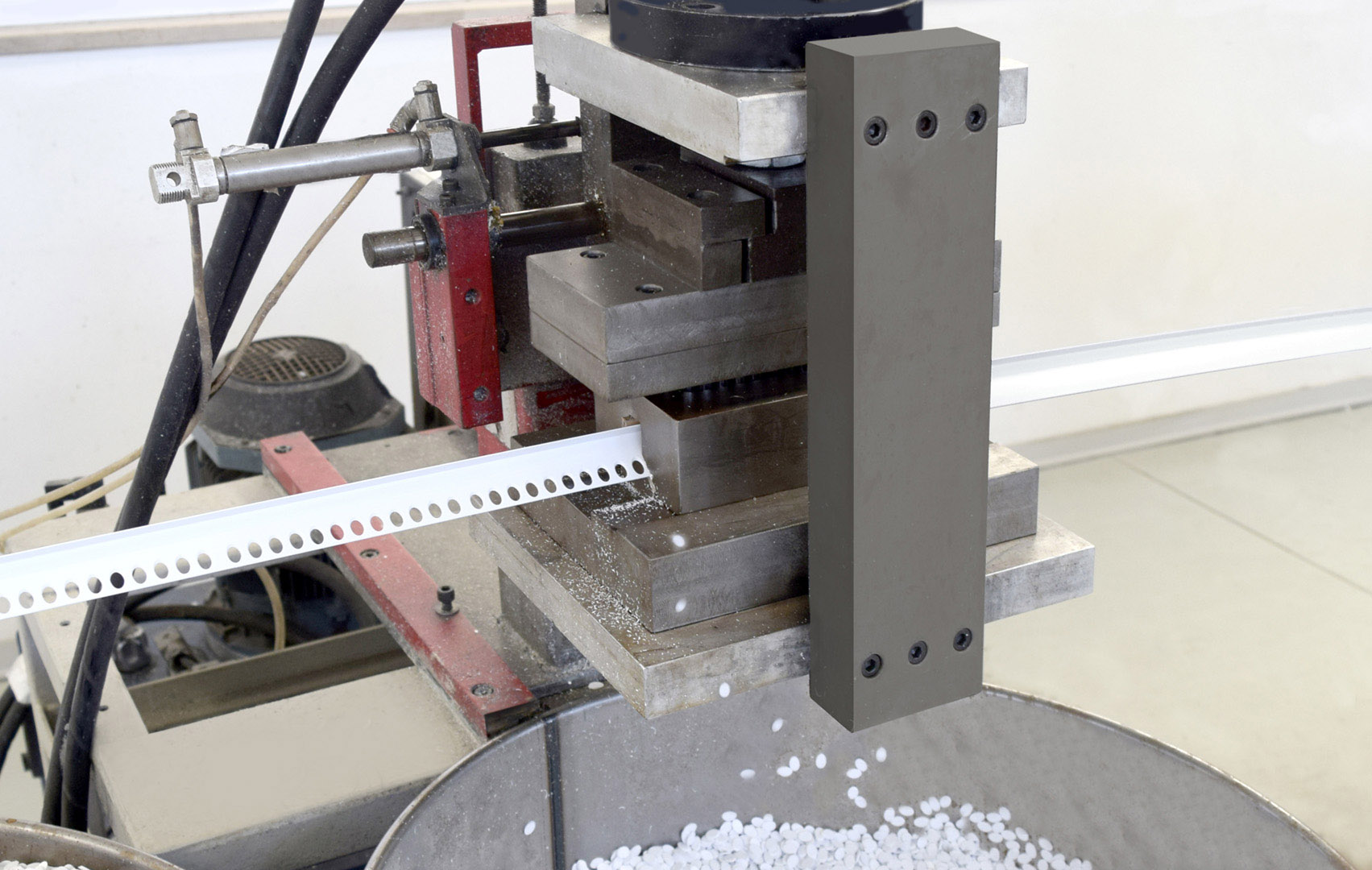

Weaving

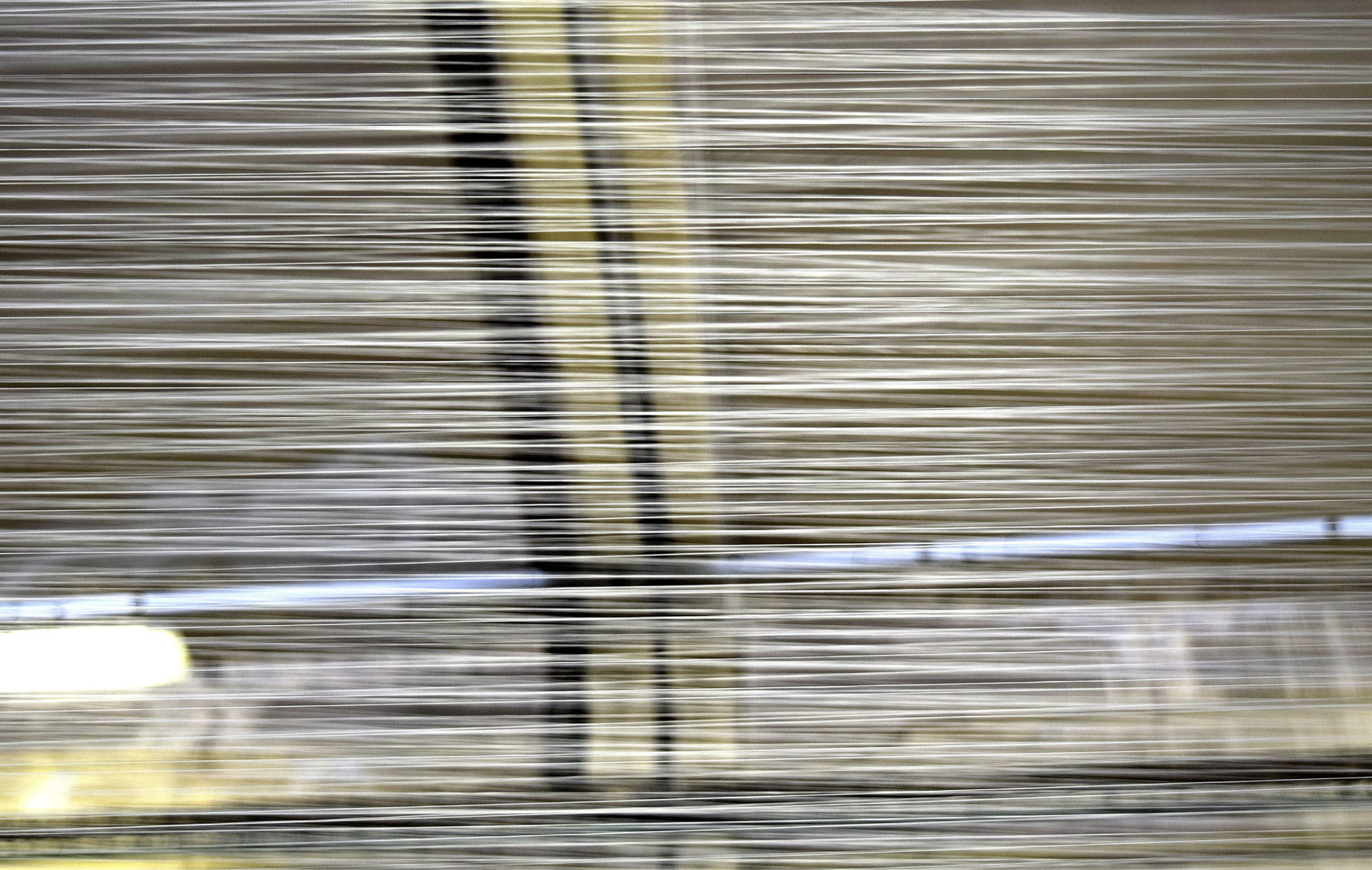

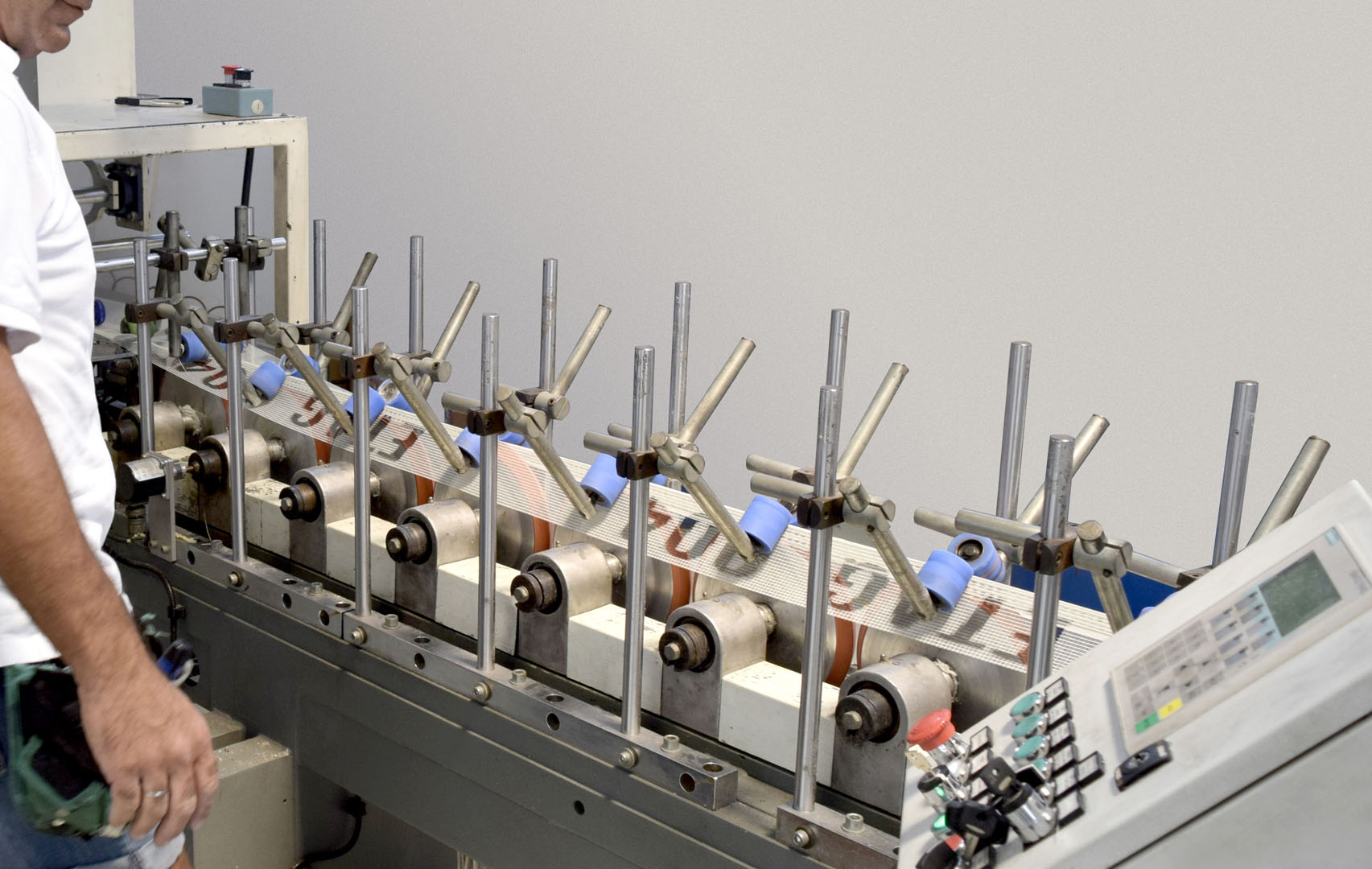

The weaving machines weave the fiber glass yarns to create a fabric according on the set weaving pattern.

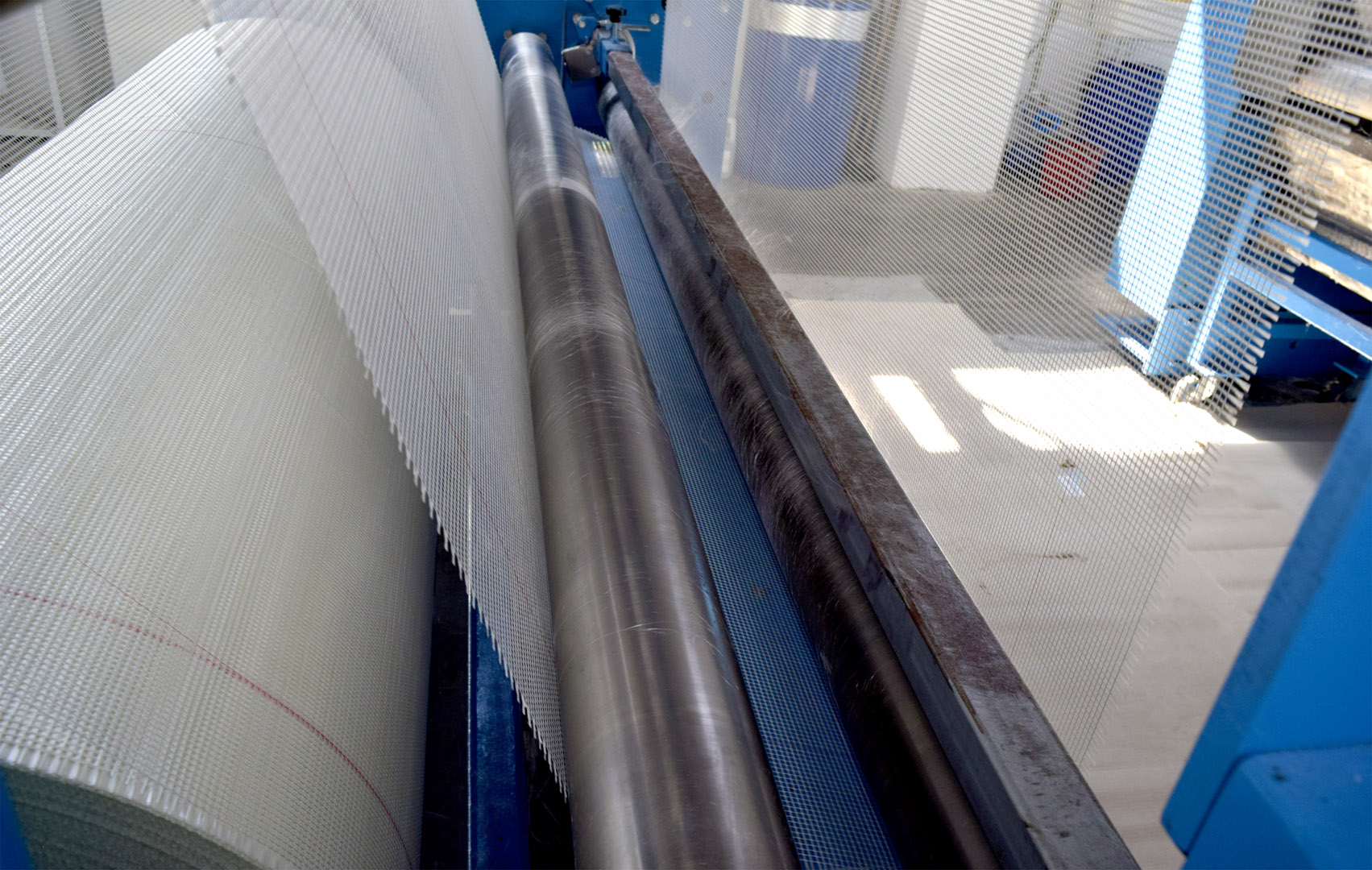

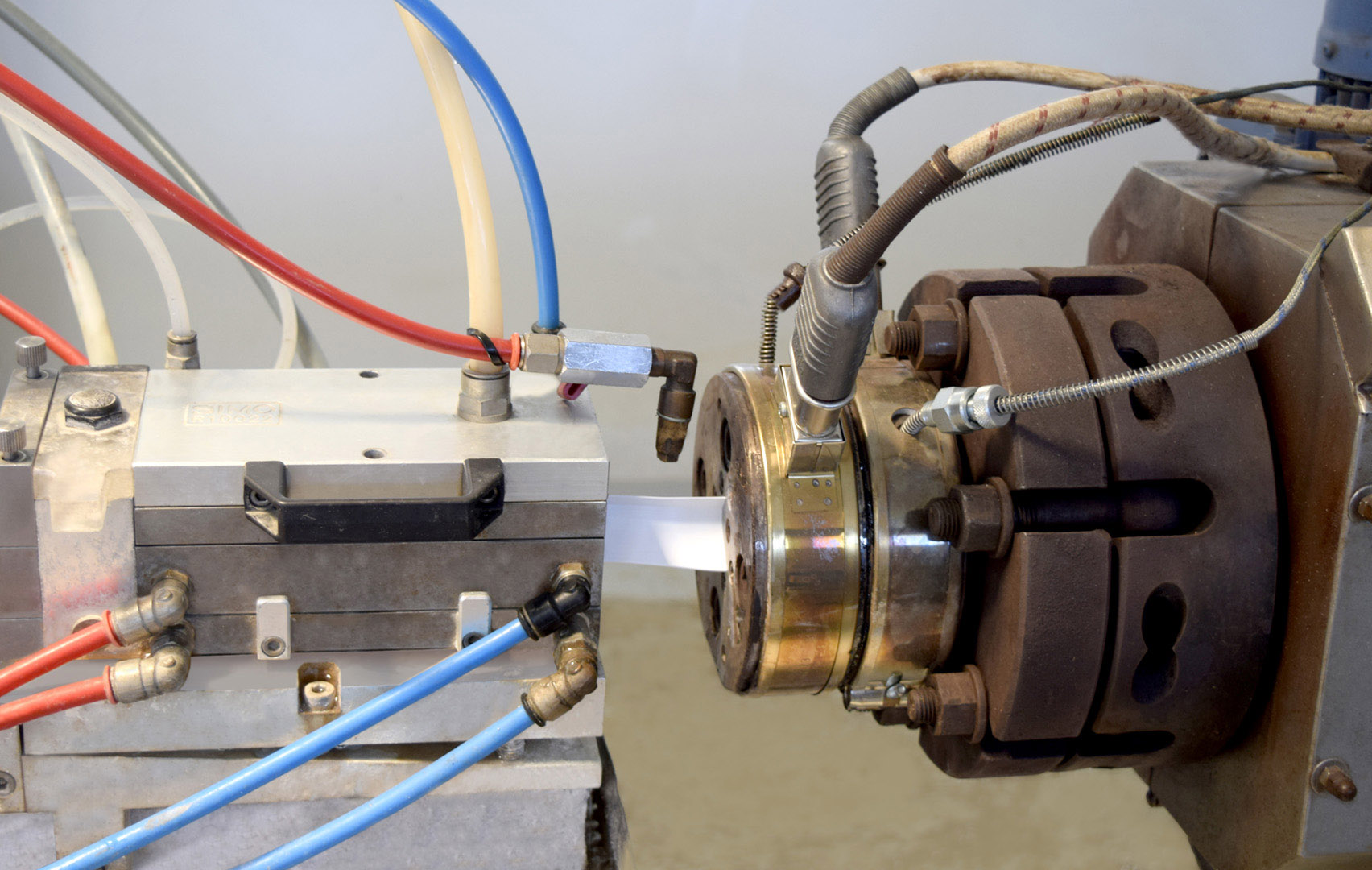

Coating process

The fiberglass fabric is coated with resin to ensure its properties of adhesion to the wall to be reinforced.

QUALITY CONTROL

The product is subjected to various quality controls during all stages of processing.

Packaging

The final products are checked, packed and palletized.

Transport

Pallet products are loaded onto the means of transport and shipped to different destinations around the world.

Know-how / Fiberglass / Production / Accessories / Customization / Logistics / Products / Video

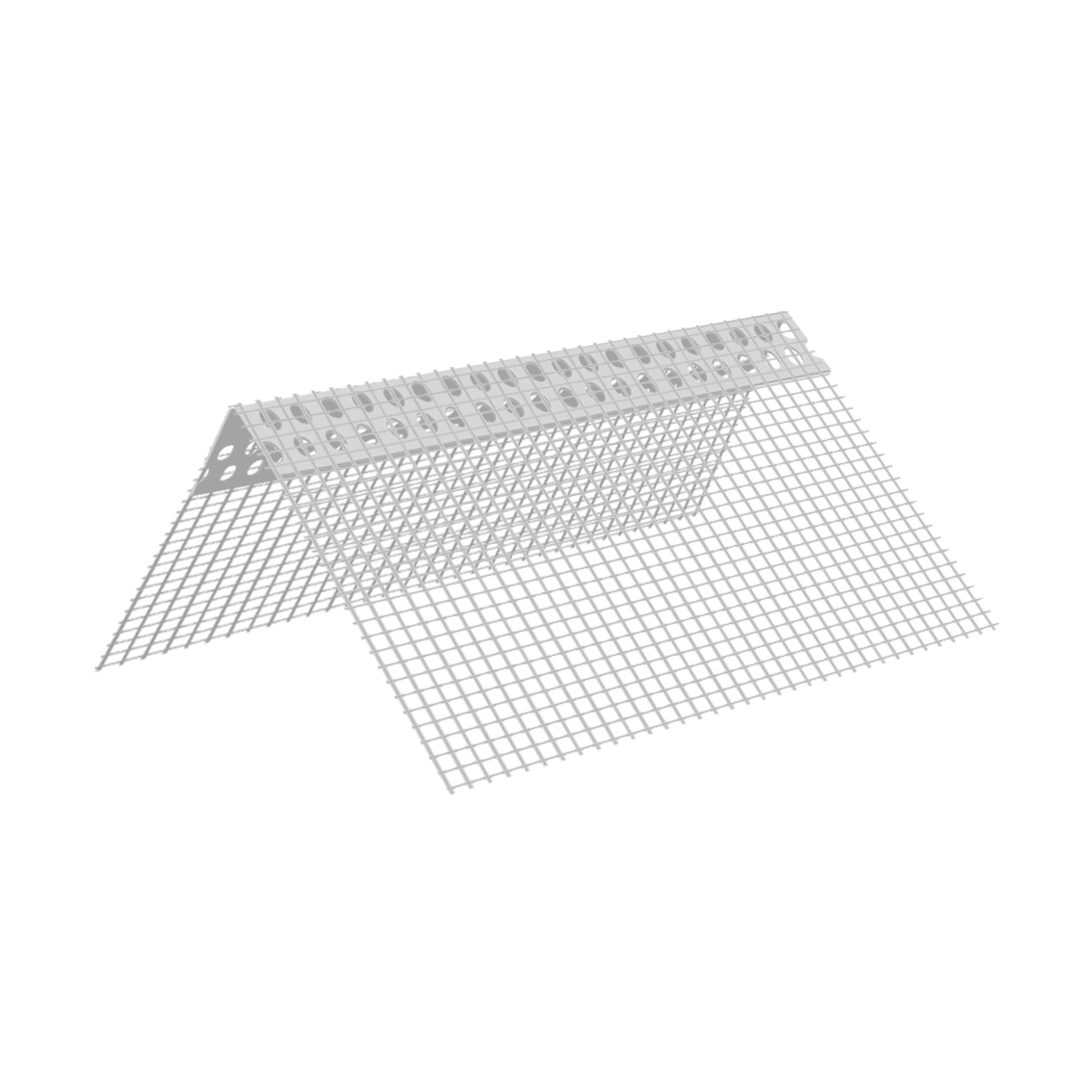

Accessories for ETICS

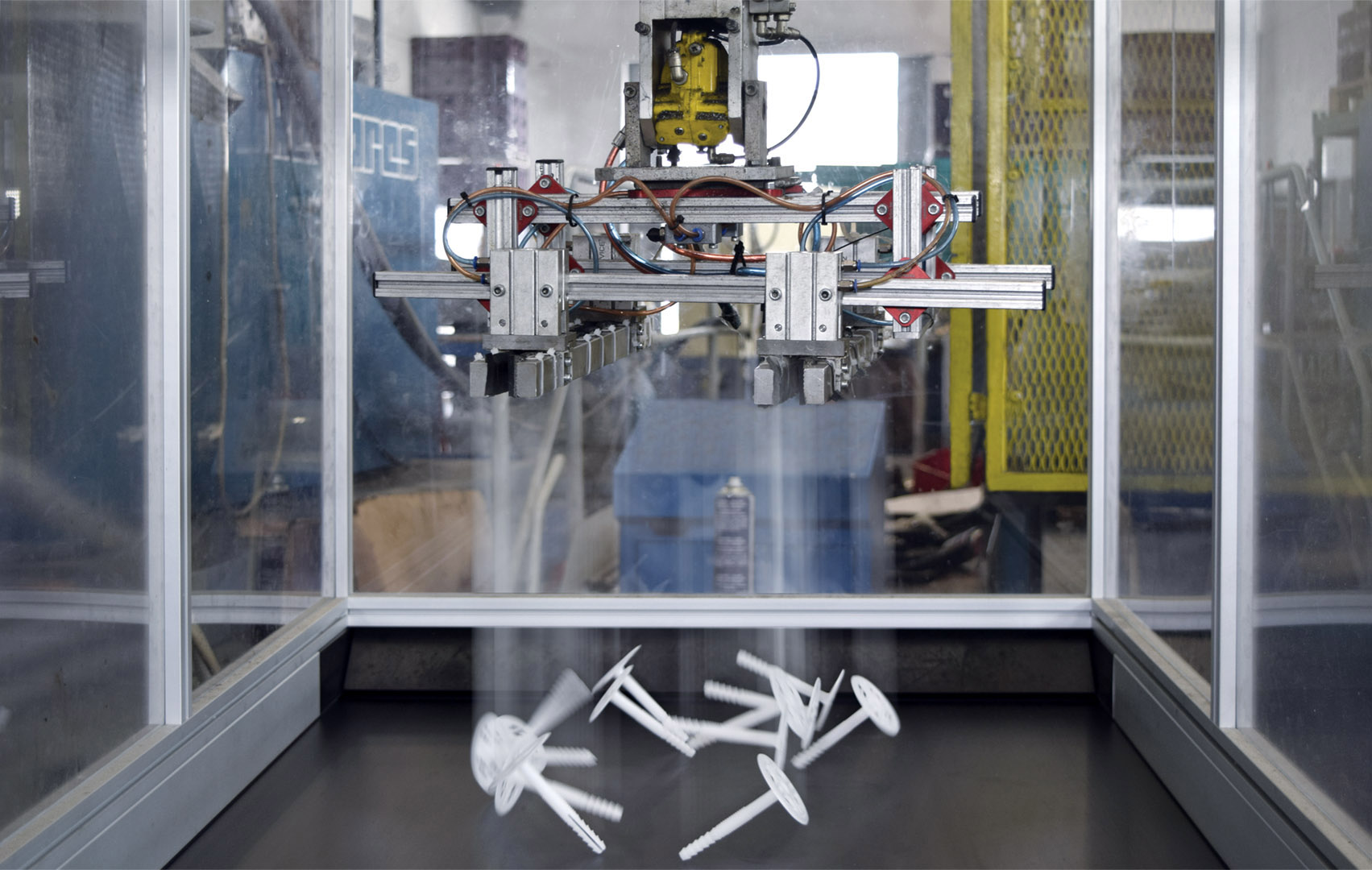

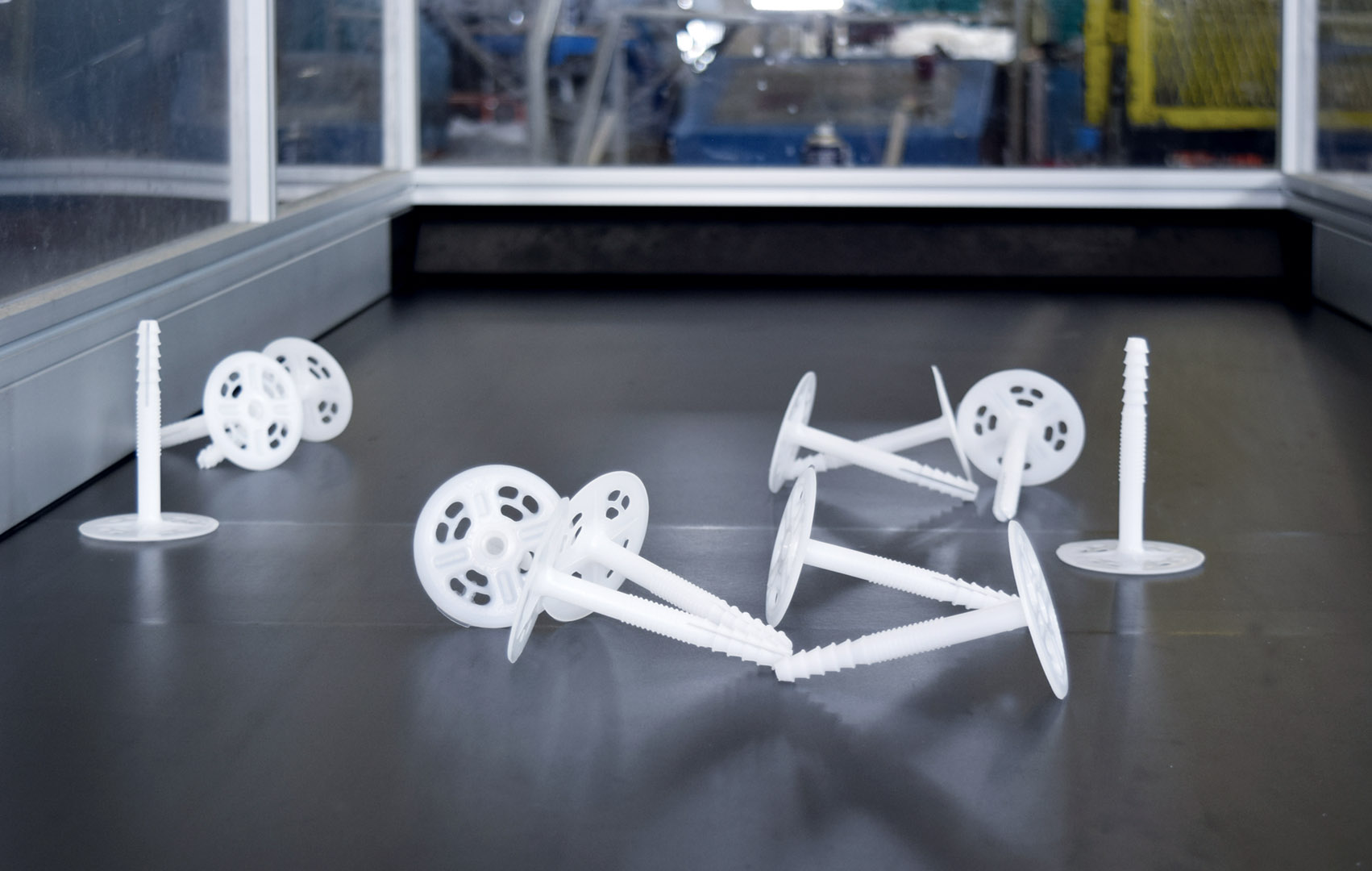

In addition to the range of different types of fiberglass fabrics, we produce a wide selection of accessories for ETICS.

These products are subject to an ongoing analysis in order to improve their solutions and characteristics.

A continuous evolution to meet the needs of the construction industry as well as to satisfy the specific needs of our customers.

specific products in the catalog

Know-how / Fiberglass / Production / Accessories / Customization / Logistics / Products / Video

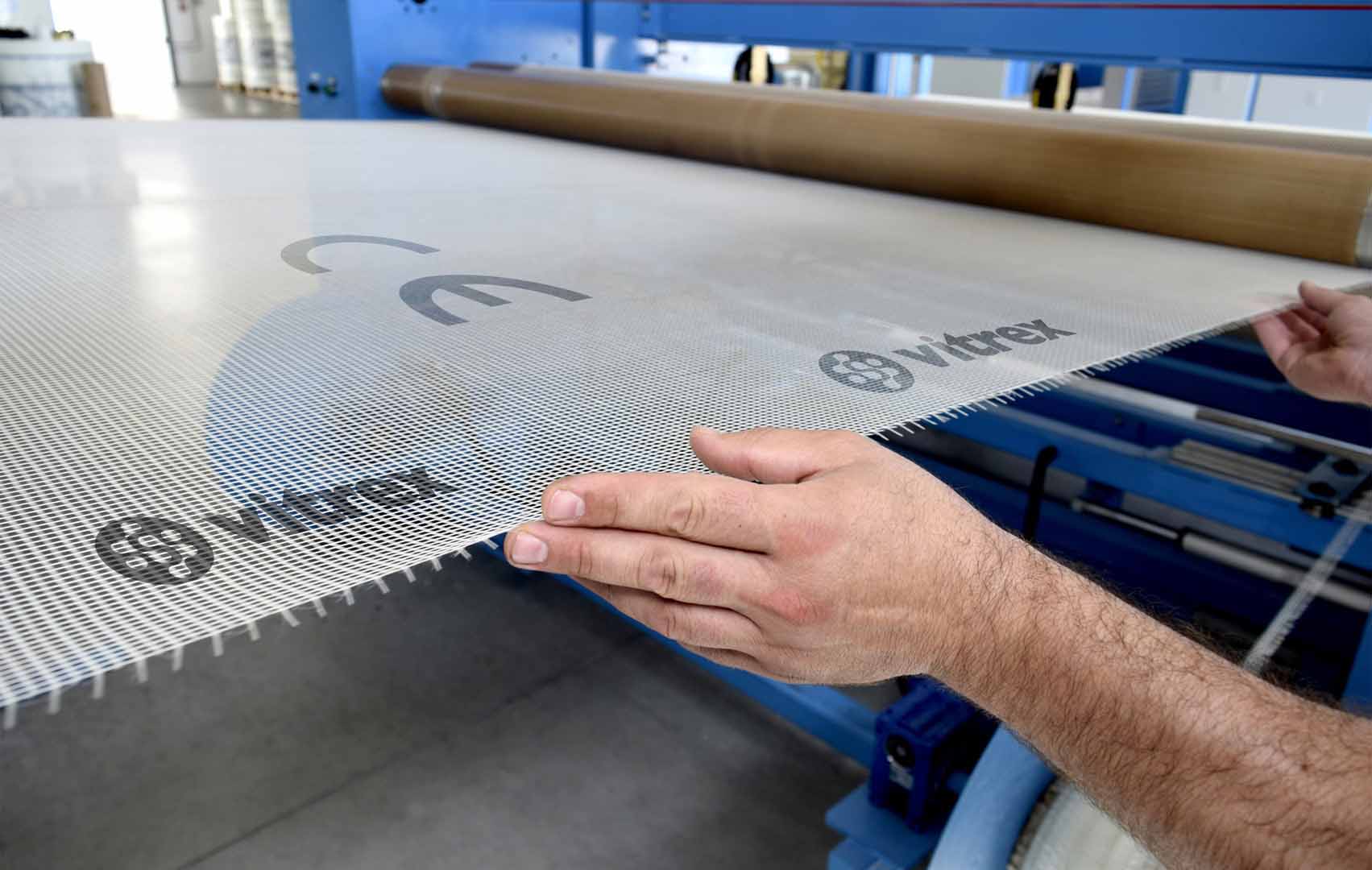

Custom printing

The apparent plastic consistency of the fiberglass meshes for building construction is therefore due to the presence of the anti-alkaline coating, which protects them over the years from the aggression of the alkalis and which can then be mixed with pigments so as to obtain different colors, designed to allow possible variations of the product.

All fiberglass meshes can be produced, if necessary, with exclusive printing customizations.

exclusive customizations

Graduated stripes

Graduated stripes

Logo

Logo

Without customization

Without customization

Customization

Customization

Know-how / Fiberglass / Production / Accessories / Customization / Logistics / Products / Video

Logistica e

Distribuzione

Thanks to advanced logistics and the fleet of 15 trucks we are able to deliver the products to all the biggest distributors on the national market.

We are also leader in the international market and export to 35 countries worldwide.

We have 50,000 square meters of covered area and 100,000 square meters of open area to complete our production process efficiently.

we export to 35 countries worldwide

square meters of storage space

a fleet of 15 trucks

Know-how / Fiberglass / Production / Accessories / Customization / Logistics / Products / Video

Vitrex Corporate Video